Wood Drying

Wood possesses the characteristic in its humidity to adapt/absorb the moisture of the environment (hygroscopic behaviour). Changes in the wood moisture cause deformations: dry wood takes up moisture in damp environment humidity, it pours. Wet wood looses humidity in dry environment and changes thereby its form, it shrinks.

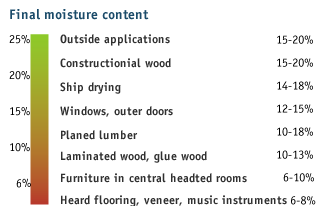

Every wood is to be brought thus into a drying condition which corresponds exactly to the climate the finished products are exposed to be installed later.

Advantages of technical wood drying

• High quality

The moisture conditions which are favourable for mushroom growth are fast gone through. Discolouration, colour defects and stretches can be avoided by a controlled drying process, in this case wood remains natural thus more beautiful. Only by means of a technical drying process, low moisture content of 8-10% can be reached. Complaints which result from a too high moisture content do not arise.

• Low costs, high flexibility, less storekeeping

Technical wood drying is in most cases cheaper than the natural drying. In a drying kiln, wood can be dried fast and economical. Technical drying ensures less storekeeping, short delivery time and increases the flexibility of a company.

• Natural pest control included

With drying temperatures over 60° C, wood pests are killed. A "pollution-free" pest control is included in a technical process in a drying kiln.

Natural pest-control without chemical additives!