For your Central Heating: Kunzel Wood Gasification Boilers

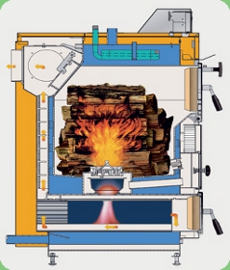

The combustion of wood takes place primarily in three stages: drying, degassing (pyrolysis) and teh actual combustion. In the development of the Kunzel wood gasification boiler, careful attention was paid to create a system in which these stages each take place in a separate part of the boiler designed for that stage rather than together in an un-controlled manner as is the case with a campfire or fireplace. The wood is dried and degassed in the various layers of the wood load in the filling chamber.

The gas produced is then mixed with pre-heated secondary air using a forced or induced draft (ID) fan in the Kunzel turbo burner, the actual core of the boiler, and subsequently burned at high temperature in the combustion chamber designed especially for this purose until few emissions remain.

This combustion technique is referred to as "bottom combustion". All Kunzel wood gasification boilers apply this principle consistently.

The Kunzel wood gasification boiler is designed for the efficient, clean combustion of pieces of natural wood (German Federal Immission Control Ordinance [BlmschV] fuel no.4). the generously dimensioned hopper holds logs up to half a meter long or one third of a meter for boilers of lesser capacity. A space- saving forced draft blower supplies combustion air to the boiler separately as primary and secondary air. The primary air is channeled via two lateral rows of air vents into the filling chamber.

The pre-heated secondary air is directed straight to the ceramic-free stainless steel burner. This specially developed turbo burner enablesthe boiler to be very compact in design and thus easy to install without sacrificing high efficiency and low emission combustion. A standard integrated electric ignition increases the heating comfort considerably. the Kunzel HV is also availabe as the HV-S model with an ID fan.

Electronic control panel 214

(for the HV boiler with forced draft blower and HV-S boiler with induced draft blower)

The electronic control panel 214 provides the basic functions for controlling a Kunzel HV wood gasification boiler with forced draft blower or an HV-S model with ID blower. It has an independently functioning fan control based on exhaust and boiler temperature, which increases the efficiency of the boiler and avoids unnecessary emissions.

In addition to boiler and fan control, the fully electronic control panel also handles the electric ignition and boiler circulation pump for the return flow increase. It is switched on automatically as soon as an exhaust temperature of 90*C is exceeded.

The boiler temperature is configured for a set point of 87*C in the factory. The boiler temperature display, main switch, start and ignition button, operating lights for the fan and pump as well as loading door and exhaust temperature display are integrated in the front of the control panel in a well-organized manner.

Set Prices (INCL. VAT):

Prices subject to change without notice.

- 1 KUENZEL HV 25 BOILER

- 1 ELECTRONIC CONTROL PANEL 214

- 1 ACCUMULATION TANK 1500 L

- 1 EXPANSION TANK 150 L

- 1 MIXING VALVE

- 1 COOLING VALVE

- 1 CAP VALVE

- 1 SAFETY VALVE

PRICE INCL. VAT € 6896,--

- 1 KUENZEL HV 30 BOILER

- 1 ELECTRONIC CONTROL PANEL 214

- 2 ACCUMULATION TANKS EACH 1000 L

- 1 EXPANSION TANK 200 L

- 1 MIXING VALVE

- 1 COOLING VALVE

- 1 CAP VALVE

- 1 SAFETY VALVE

PRICE INCL. VAT € 8284,--

- 1 KUENZEL HV 40 BOILER

- 1 ELECTONIC CONTROL PANEL 214

- 2 ACCUMULATION TANKS EACH 1500 L

- 1 EXPANSION TANK 300 L

- 1 MIXING VALVE

- 1 COOLING VALVE

- 1 CAP VALVE

- 1 SAFETY VALVE

PRICE INCL. VAT € 9723,--

- 1 KUENZEL HV 50 BOILER

- 1 ELECTRONIC CONTROL PANEL 214

- 2 ACCUMULATION TANKS EACH 1500 L

- 1 EXPANSION TANK 300 L

- 1 MIXING VALVE

- 1 COOLING VALVE

- 1 CAP VALVE

- 1 SAFETY VALVE

PRICE INCL. VAT € 10592,--

- 1 KUENZEL HVS 25 BOILER

- 1 ELECTRONIC CONTROL PANEL 214

- 1 ACCUMULATION TANK 1500 L

- 1 EXPANSION TANK 150 L

- 1 MIXING VALVE

- 1 COOLING VALVE

- 1 CAP VALVE

- 1 SAFETY VALVE

PRICE INCL. VAT € 7694,--

- 1 KUENZEL HVS 30 BOILER

- 1 ELECTRONIC CONTROL PANEL 214

- 2 ACCUMULATION TANKS EACH 1000 L

- 1 EXPANSION TANK 200 L

- 1 MIXING VALVE

- 1 COOLING VALVE

- 1 CAP VALVE

- 1 SAFETY VALVE

PRICE INCL. VAT € 9103,--

- 1 KUENZEL HVS 40 BOILER

- 1 ELECTRONIC CONTROL PANEL 214

- 2 ACCUMULATION TANKS EACH 1500 L

- 1 EXPANSION TANK

- 1 MIXING VALVE

- 1 COOLING VALVE

- 1 CAP VALVE

- 1 SAFETY VALVE

PRICE INCL. VAT € 10542,--

- 1 KUENZEL HVS 50 BOILER

- 1 ELECTRONIC CONTROL PANEL 214

- 2 ACCUMULATION TANKS EACH 1500 L

- 1 EXPANSION TANK 300 L

- 1 MIXING VALVE

- 1 COOLING VALVE

- 1 CAP VALVE

- 1 SAFETY VALVE

PRICE INCL. VAT € 11421,--

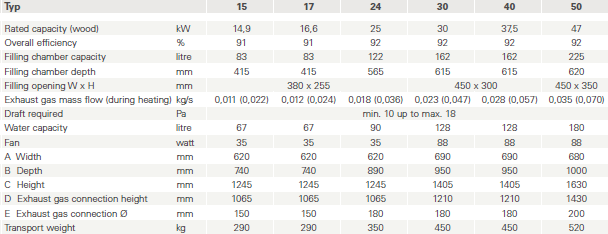

Boiler Technical Parameters

In-Depth description of our Boilers:

To view the following files, Abode Reader needs to be installed on your computer. If you do not have it, click the icon below to download it.

We can supply quotations for any size of boiler including installation and delivery.

For more information, click here: www.kuenzel.de