The diversity of the organic fuels knows practically no limits. To use this is the task of this boiler series.

A round cyclone combustion chamber with counter-rotational turbine air supply (rotation combustion) stands for a high degree of efficiency and complete burning of the fuel. The primary air supply is undertaken via the laterally set high temperature cast iron blocks. Everything which sluggishly degases or burns is slowly moved with chain shovels over the boiler floor to the ash discharge shaft and thereby burnt optimally.

BURNS >>>

- Connector.

Woodchips

- Connector.

Pellets

- Connector.

Sawdust

Boiler Cross Section

- Discharge Channel

- Maintenace Flap

- Discharger system motor

- Rotary valve

- Feed auger motor

- Ignition

- Primary combustion blower

- Secondary combustion blower

- Combustion chamber

- Combustion chamber door

- Post combustion/drop out chamber

- Post combustion chamber door

- Heat exchanger tubes with de-ashing

- Drive for de-ashing auger

- Flue gas temperature sensor

- Lambda sensor

- Flue gas blower/connection

- Ash cleaning system

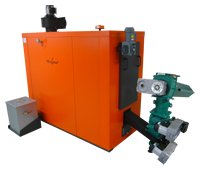

Biomass Boilers

RHK-AK 30

• heat output 0 – 36 kW

• Suitable for chips, pellets and biomass

• Automatic cleaning

• Operations modes ignition or continuous

• De-ashing system via chain

• Ash Box 45 Litre

RHK-AK 50

• heat output 0 – 50 kW

• Suitable for chips, pellets and biomass

• Automatic cleaning

• Operations modes ignition or continuous

• De-ashing system via chain

• Ash Box 45 Litre

RHK-AK 60

• heat output 0 – 60 kW

• Suitable for chips, pellets and biomass

• Automatic cleaning

• Operations modes ignition or continuous

• De-ashing system via chain

• Ash Box 45 Litre

RHK-AK 75

• heat output 0 – 75kW

• Suitable for chips, pellets and biomass

• Automatic cleaning

• Operations modes ignition or continuous

• De-ashing system via chain

• Ash Box 45 Litre

RHK-AK 100

• heat output 0 – 100 kW

• Suitable for chips, pellets and biomass

• Automatic cleaning

• Operations modes ignition or continuous

• De-ashing system via chain

• Ash Box 45 or 240 Litre

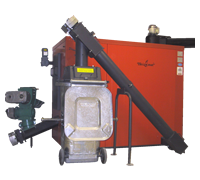

RHK-AK 150

LOW DESIGN

• heat output 0 – 150 kW

• Suitable for chips, pellets and biomass

• Automatic cleaning

• Operations modes ignition or continuous

• De-ashing system via chain

• Ash Box 240 or 900 Litre

RHK-AK 150

HIGH DESIGN

• heat output 0 – 150kW

• Suitable for chips, pellets and biomass

• Automatic cleaning

• Operations modes ignition or continuous

• De-ashing system via chain

• Ash Box 240 or 900 Litre

RHK-AK 200 (low design)

• heat output 0 – 198kW

• Suitable for chips, pellets and biomass

• Automatic cleaning

• Operations modes ignition or continuous

• De-ashing system via chain

• Ash Box 240 or 900 Litre

RHK-AK 200 (high design)

• heat output 0 – 198kW

• Suitable for chips, pellets and biomass

• Automatic cleaning

• Operations modes ignition or continuous

• De-ashing system via chain

• Ash Box 240 or 900 Litre

RHK-AK 300

• heat output 0 – 300 kW

• Suitable for chips, pellets and biomass

• Automatic cleaning

• Operations modes ignition or continuous

• De-ashing system via chain

• Ash Box 240 or 900 Litre

RHK-AK 400

• heat output 0 – 400 kW

• Suitable for chips, pellets and biomass

• Automatic cleaning

• Operations modes ignition or continuous

• De-ashing system via chain

• Ash Box 900 Litre

RHK-AK 500

• heat output 0 – 500 kW

• Suitable for chips, pellets and biomass

• Automatic cleaning

• Operations modes ignition or continuous

• De-ashing system via chain

• Ash Box 900 Litre

RHK-AK 600

• heat output 0 – 600 kW

• Suitable for chips, pellets and biomass

• Automatic cleaning

• Operations modes ignition or continuous

• De-ashing system via chain

• Ash Box 900 Litre

RHK-AK 800

• heat output 0 – 800 kW

• Suitable for chips, pellets and biomass

• Automatic cleaning

• Operations modes ignition or continuous

• De-ashing system via chain

• Ash Box 900 Litre

RHK-AK 1000

• heat output 0 – 900 kW

• Suitable for chips, pellets and biomass

• Automatic cleaning

• Operations modes ignition or continuous

• De-ashing system via chain

• Ash Box 900 Litre